Our Fabrication Process & Machinery

Precision

From Start to Finish

State-of-the-Art Technology for Precision Stone Fabrication

Digital Templating

Prodim Proliner or LT3 Raptor

Used onsite to create a precise laser digital template of the client's cabinets and walls, eliminating manual errors.

Connection: Sends the exact dimensions to the shop, creating the blueprint that guides all subsequent cutting machines.

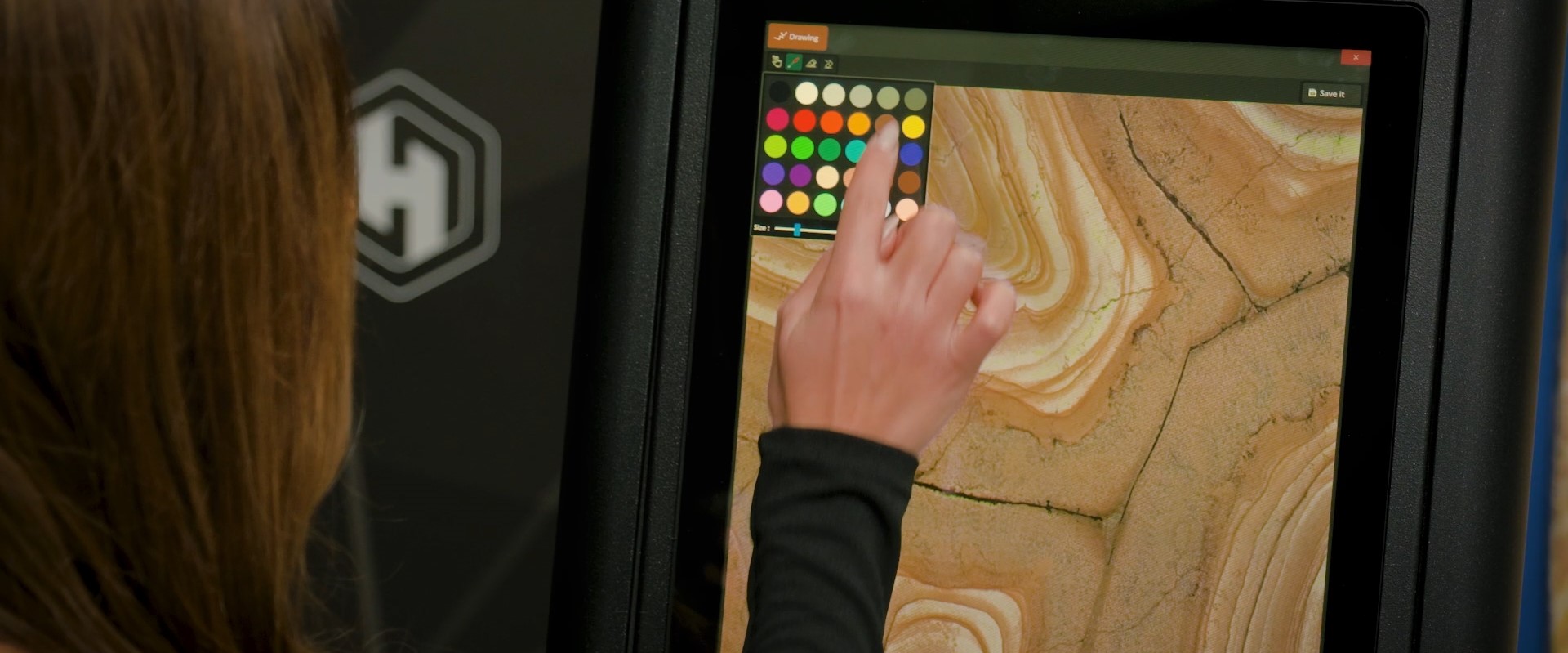

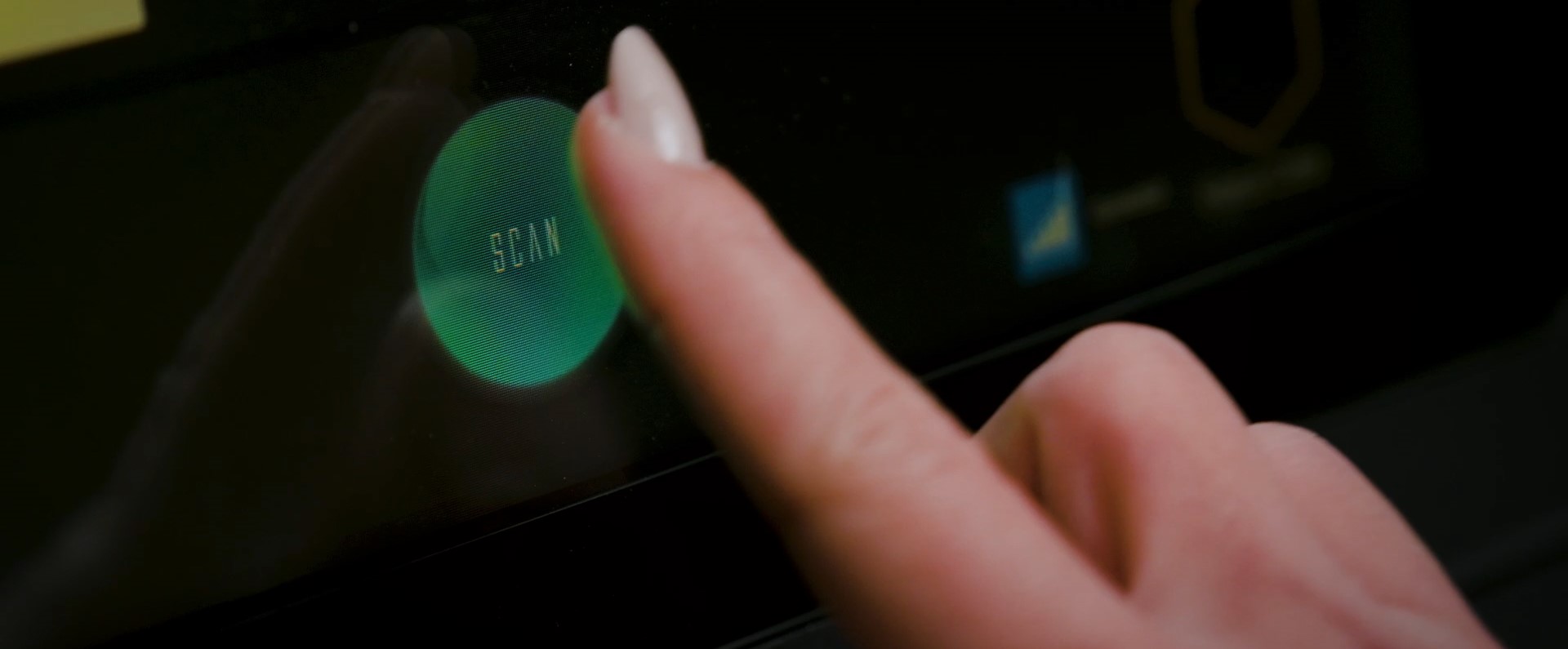

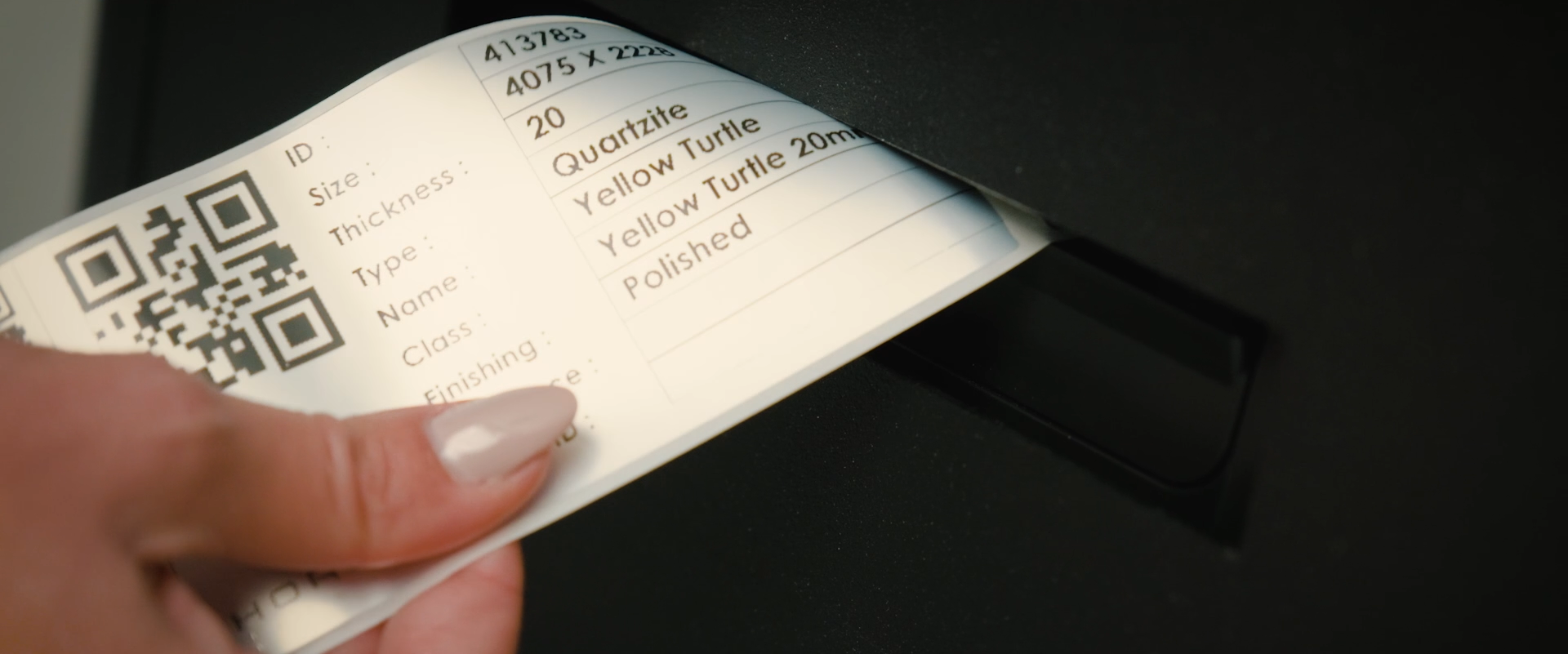

Slab Scanning

Iris Scanner

Captures a high-resolution "digital twin" of the stone slab so you can visualize veins and defects perfectly.

Connection: Allows the fabricator to overlay the Proliner/Raptor templates onto the stone image for perfect vein matching before cutting.

Heavy Cutting

Voyager XP (CNC Saw)

A powerful 5-axis saw designed for speed and precision on straight cuts and complex miter angles.

Connection: Uses the layout from the Iris Scanner to cut the main pieces of the project efficiently, preparing them for detailing.

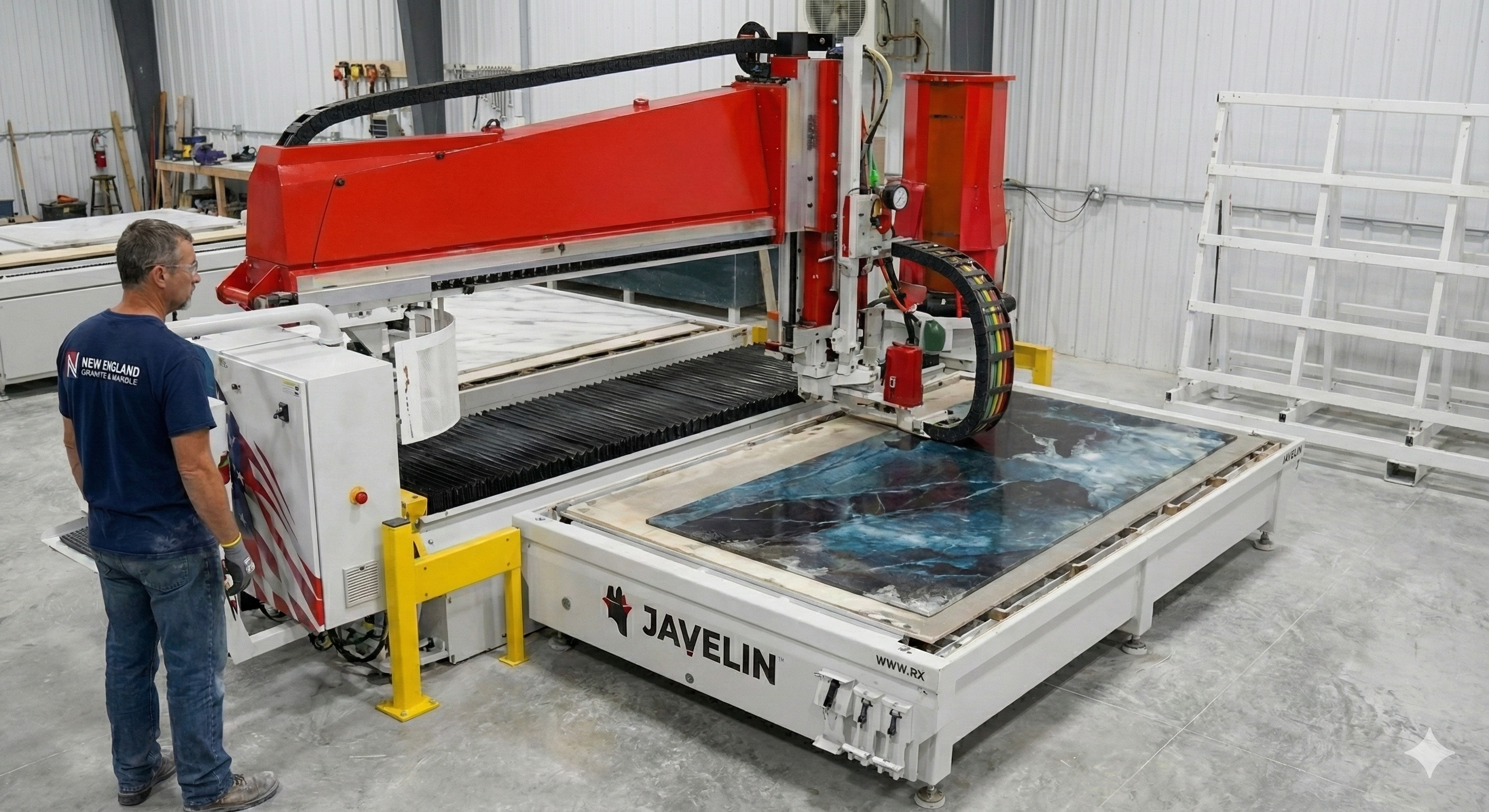

Precision Cutting

Javelin (CNC Sawjet)

Combines a diamond saw with a high-pressure waterjet to execute intricate curves and sink cutouts that a standard saw cannot do.

Connection: Refines the work of the Voyager XP by handling complex geometries, ensuring the piece is perfectly shaped for finishing.

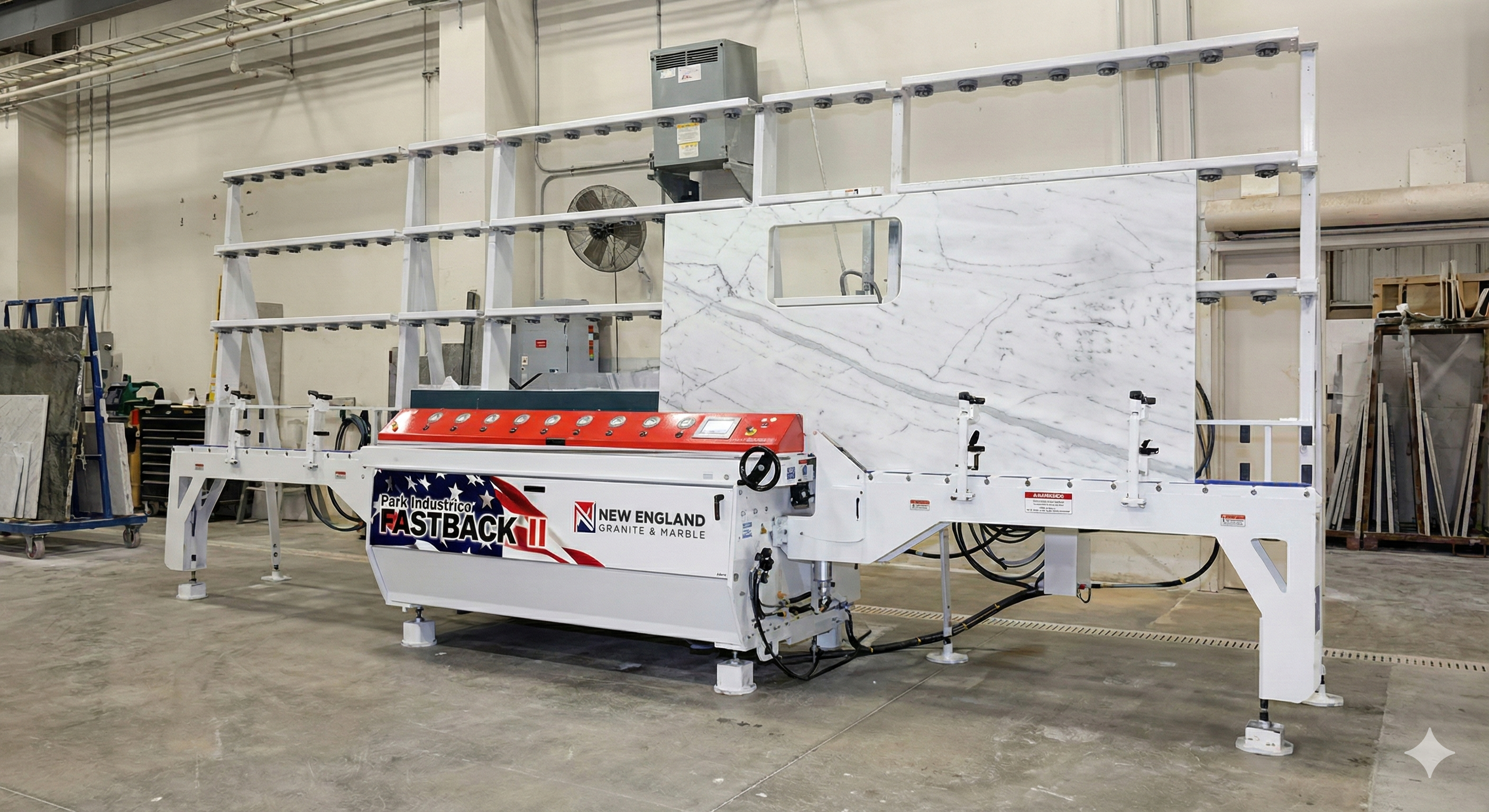

Edge Polishing

Fastback II

Automates the edge polishing process for backsplashes and countertops, producing a showroom shine in minutes.

Final Step: Takes the cut pieces from the Voyager/Javelin and applies the final mirror-finish, making them ready for installation.

.png)

.png)

.png)

.png)

.png)

.png)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.png)

.png)

.png)

.png)

.png)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)